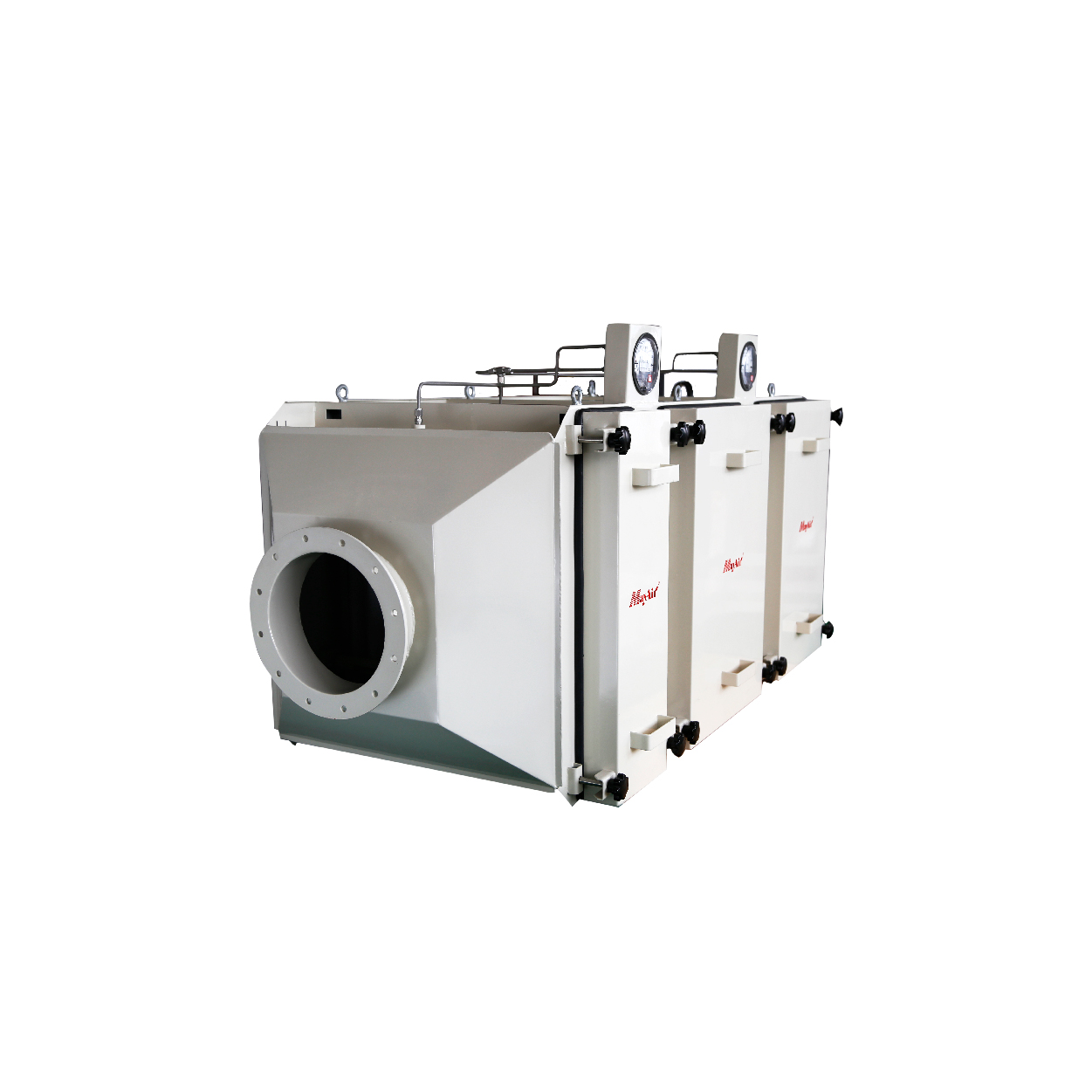

Product Description

Structure Description:

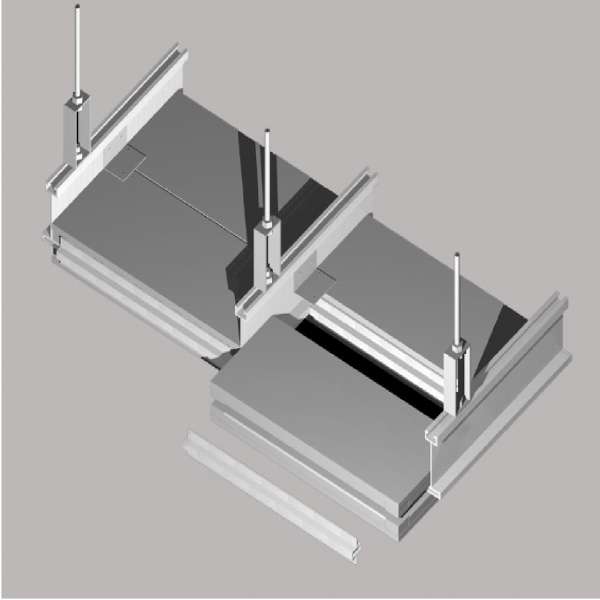

1. Highly flexible modular assembly. Unit can be assembled based on air flow and available space.

2. Zero leakage valve technology ensures product reliability.

3. High precision welding technology ensures product reliability.